X5 - Storage Media Copy System

Requirements

That is what we have implemented

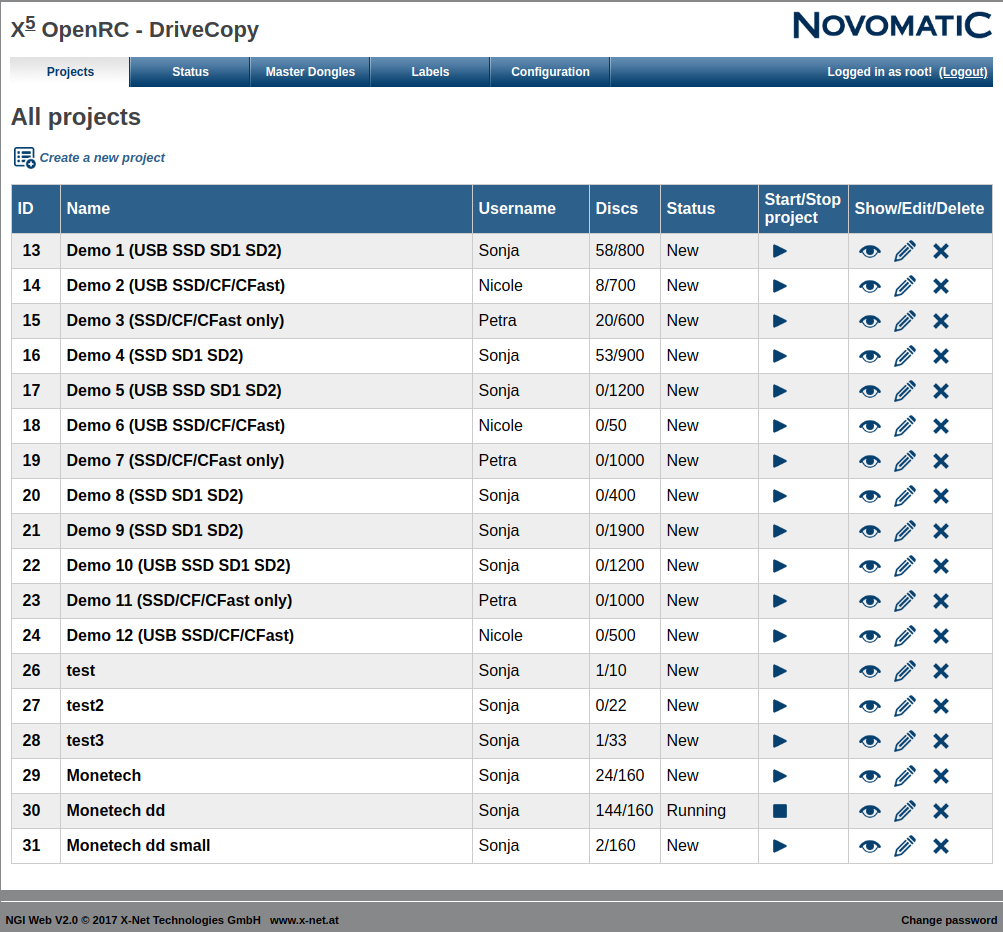

- Secure: Each data carrier can be loaded with individual data in automated processes, e.g. with high-quality software or a unique software key

- Easy to use: X⁵ is integrated directly into the production line, automating the creation of 1:1 copies.

- Data is written and verified asynchronously and automatically, with production peaks supported by clusters.

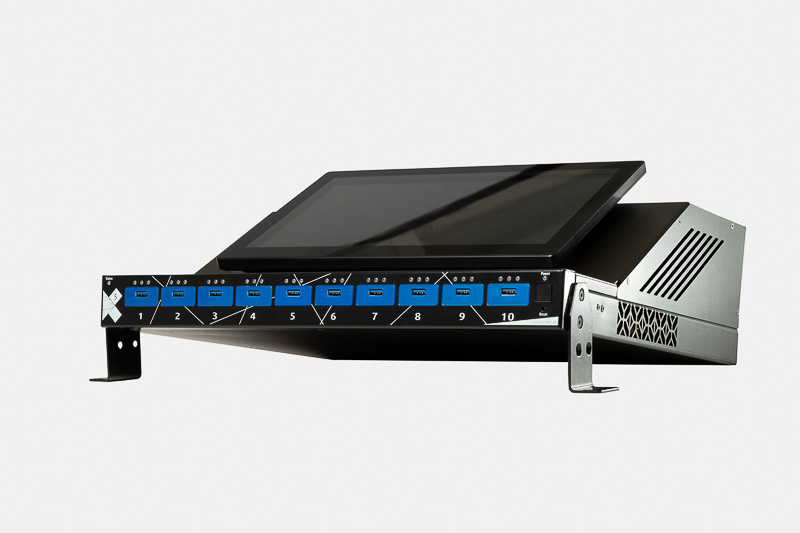

- X5 writes to a variety of data media and media sets. Adapters are utilised for this purpose, and/or different modules are combined into one system

- Scalable: hardware and software have a modular design. The number of modules can be adjusted according to requirements, desired capacity and available data volume.

Thomas Aiglesberger

Software & Head of Hardwaredevelopment

Nikolaus Dürk

Founder and CEO